Physical-Chemical Transformer Diagnostics Department today

Physical-Chemical Transformer Diagnostics Department today

Physical-Chemical Transformer Diagnostics

Activities

The main area of activity of the Physical-Chemical Transformer Diagnostics Department is fundamental and applied research into physical and chemical diagnostics in high voltage devices.

Areas of work

The Physical-Chemical Transformer Diagnostics Department carries out activities in the fields of energy chemistry and physical research:

- physical and chemical diagnostic testing of power and instrument transformers;

- testing of transformer oils and paper insulation according to the requirements of IEC specifications and directives, international recommendations, Slovenian legislation, i.e. in accordance with standard procedures,

- issuing expert physical and chemical diagnostic assessments in the area of operational reliability of new and old transformers,

- applied research in physical and chemical diagnostics,

- use of recognised methods and development of advanced non-destructive diagnostic methods for the early detection of transformer faults, preventive maintenance, prolongation of life span and the operational reliability of transformers,

- assessment of the remaining life span and technological elaboration in the area of investment, maintenance and operational revitalisation activities in transformers and other high-voltage equipment,

- consulting, education, organisation of conferences and meetings of working groups,

- research and inter-laboratory "Round Robin" testing in the working groups of the CIGRE international conference and the IEC international electric technology commission in the area of developing standards for physical-chemical diagnostics of high-voltage insulated systems. The department experts also participate in the SIST TPD technical committee in the area of liquid and gas dielectrics.

Tests

This test is used to control the functional ability of the transformer/apparatus and for the optimum maintenance that ensures the expected transformer's life period.

The test encompasses:

- physical-chemical and dielectric oil analyses,

- operating ability and oil durability assessment,

- insulation paper and oil humidity assessment,

- Recommendations for maintenance or other measures and tests.

An oil sample may be taken during normal operation using a clean, dry 1 l bottle. Sampling may be carried out by a ISO/IEC 17025 accredited and qualified expert. For any additional information please call +386 1 474 3661.

This test is used to control and diagnose disturbances in operating energy and instrument transformers, and also in new transformers during factory tests. With a systematic control (once per year) we can warn about the disturbances in the transformer, before any serious faults or the Buchholz relay occur.

The test encompasses:

- analysis of the gases dissolved in transformer oil (hydrogen, methane, ethane, ethylene,

- acetylene, CO, CO2, oxygen, nitrogen),

- diagnosis of the condition of the transformer; detection of thermal and electrical faults at an early stage and the assessment of events accompanying the Buchholz relay or shut down,

- assessment of transformer operating reliability,

- Recommendations for further measures and tests.

An oil sample may be taken during normal operation using a gas-tight 250 ml syringe. In exceptional situations it is also possible to use a dry 1 l bottle. Sampling may be carried out by a ISO/IEC 17025 accredited and qualified expert. For any additional information please call +386 1 474 3661.

This test is used to control and diagnose incipient thermal faults, cooling system faults, damage to the paper insulation, and the rate of ageing of the paper insulation in power and instrument transformers in operation, but also in new transformers during factory tests. With systematic checks once a year we can detect incipient faults within the transformer even before they lead to serious faults, trip the Buchholz relay, or noticeably shorten the life span.

The test encompasses:

- analysis of 5 furanic compounds dissolved in the transformer oil,

- diagnosis of the condition of the transformer; detection of paper damages or thermal incipient faults at an early stage and assessment of the events accompanying the Buchholz relay or transformer shut down,

- assessment of the degree of degradation or ageing of paper insulation and the operational reliability of the transformer,

- recommendations for further measures and tests.

An oil sample may be taken during normal operation using a gas-tight 250 ml syringe. In exceptional situations it is also possible to use a dry 1 l bottle. Sampling may be carried out by a ISO/IEC 17025 accredited and qualified expert. For any additional information please call +386 1 474 3661.

The HPLC test is carried out with the same sample as the DGA test.

On the basis of the results of combined testing, we assess the condition of the instrument transformer with regard to both the ageing and moisture content of the insulation system and also possible electrical and thermal incipient faults (the possibility of explosion), and the quality of the insulating oil and paper insulation. Based on these results we can determine potential reductions in reliable and safe operation or the need to take the transformer out of service. Combined testing can be carried out using only a small amount of sample oil, which we sample using a gas-tight 250 ml syringe when the transformer is not in operation, ideally as soon as possible after it is shut down. Sampling may be carried out by a ISO/IEC 17025 accredited and qualified expert.

For any additional information please call +386 1 474 3661.

Analysis of the degree of polymerisation of the paper insulation is not a routine test used to monitor a transformer in operation because it is necessary to take a sample of the paper insulation, which requires at least partially opening the transformer.

DP analysis of the paper insulation allows us to assess its mechanical (tensile) strength, which is a critical property used to determine the safe operation of the transformer, particularly upon short-circuit or other mechanical stresses.

The analysis gives information on the condition of the paper insulation at the sampling site, so we usually choose a site for testing (such as the exit point of the lead from the windings) where a lower level of polymerization and, therefore, weaker paper can be expected.

This test is carried out when the results of the HPLC testing indicate that the paper insulation is already somewhat degraded or damaged.

Data on the degree of polymerisation are absolutely required when preparing a diagnosis of the remaining life span of the transformer, or when planning any kind of transformer revitalisation or maintenance activities.

The transformer servicer carries out the sampling. There must be an agreement regarding the sampling site and sampling method. For any additional information please call +386 1 474 3661.

PCB-contaminated oil is rated a special waste because it is poisonous and ecologically hazardous, so it is obligatory to perform an analysis of the presence of PCBs in oil before it is disposed of or before performing extensive work on the transformer.

In compliance with the current Slovenian legislation, each apparatus with more than 5 litres of oil must have a document (a manufacturer's declaration or the oil test report) showing the absence of PCBs in the oil.

Laboratory

Chemistry laboratory with equipment for:

- Carrying out physical-chemical analyses to determine functional capabilities and the degree of ageing of transformers and turbine oils in compliance with IEC standards,

- Carrying out analyses to evaluate the mechanical strength of paper insulation in compliance with IEC standard.

IR spectroscopy laboratory to measure the inhibitor content, to identify types, degree of ageing and contamination of transformer oils in compliance with IEC standards.

Chromatography laboratory with:

- Gas chromatography for Dissolved Gas Analysis to determine transformer condition with regard to incipient thermal and electrical faults or actual faults in compliance with IEC standards,

- HP Liquid chromatography for furanic compounds determination to monitor ageing, faults, and evaluation of mechanical strength of paper insulation in compliance with IEC standards.

Certificates

Contacts

PHONE: +386 1 474 36 60

Head of department

Biljana Čuček, M. Sc. Chem.

Phone: +386 1 474 36 60

Mobile: +386 51 635 504

E-mail:

Gallery

Physical-Chemical Transformer Diagnostics Department today

Physical-Chemical Transformer Diagnostics Department today

Sensor diagnostics of gases dissolved in oil

Sensor diagnostics of gases dissolved in oil

Oil sampling from the largest 1200 MVA phase shift transformer in Slovenia, Divača transformer station

Oil sampling from the largest 1200 MVA phase shift transformer in Slovenia, Divača transformer station

Dissolved gas analysis for discovering transformer defects today

Dissolved gas analysis for discovering transformer defects today

The largest 1200 MVA phase shift transformer in Slovenia, Divača transformer station

The largest 1200 MVA phase shift transformer in Slovenia, Divača transformer station

Gas chromatograph

Gas chromatograph

The beginnings of gas cromatography for transformer diagnostics in 1985

The beginnings of gas cromatography for transformer diagnostics in 1985

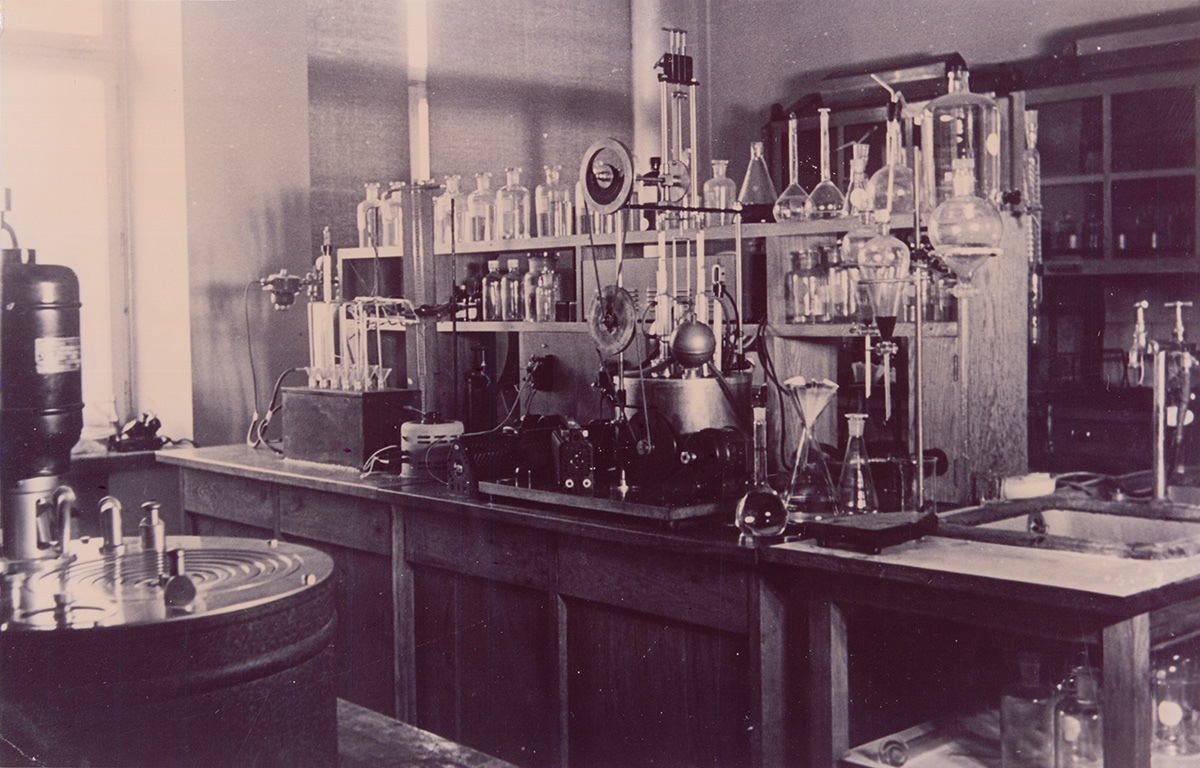

The Laboratory of the Expert Group for Chemistry and Physical Research Laboratory in 1952

The Laboratory of the Expert Group for Chemistry and Physical Research Laboratory in 1952

The awarding of the Dutch Raad vor Accreditatie certificate ISO/ IEC 17025

The awarding of the Dutch Raad vor Accreditatie certificate ISO/ IEC 17025